Skystone (2019-2020)

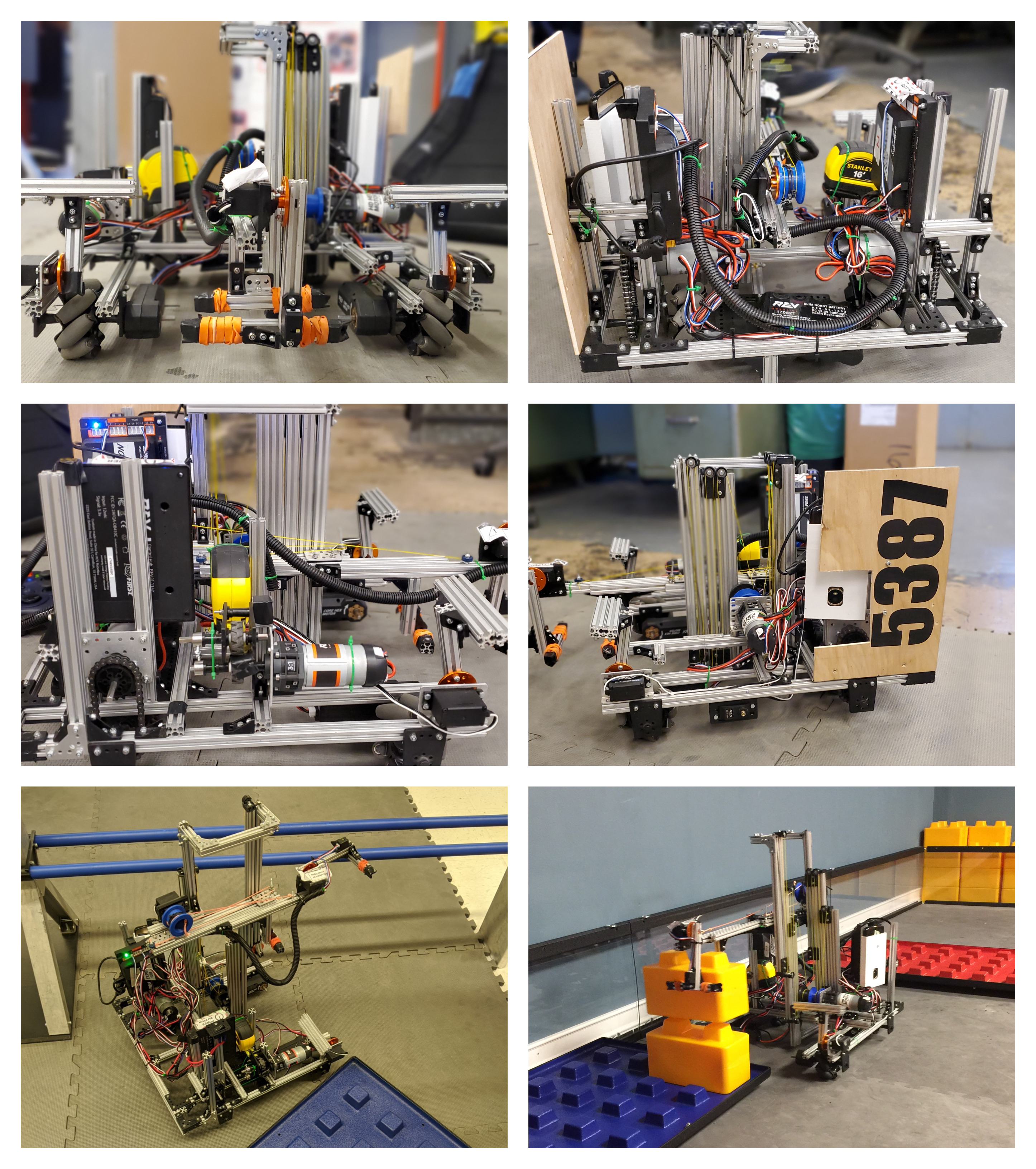

For our final robot design, we centered around a vertical 2 stage linear slide, connected to a single state horizontal slide. Both slides make use of pulleys and UHMWPE cord to extend, with the vertical slide actuated by a REV core hex motor, and the horizontal slide actuated by a continuous rotation servo. Additionally, the vertical slide uses gravity along with surgical tubing to return, while the horizontal slide uses a UHMWPE cord pulling back, connected to the servo. The vertical slide gives us the height we need to stack stones, while the horizontal slide allows our robot to reach into the build site, and also allows us to make fine adjustments when picking up and placing stones. To coil and uncoil the strings, we make use of 3d printed drums that are sized so that we get enough torque to reliably move the axes, while also having plenty of speed. For motion around the field, we use standard drive wheels, geared slightly down for more precision and torque, and omni wheels on the front, for better maneuverability. Our stone grabbing assembly consists of one fixed arm, and another moving arm, controlled by a geared down servo. It is able to reliably pick up both the stones, and our team’s capstone, and place them on the building side, and uses rubber bands to generate more grip. The fixed arm of the grabbing assembly also serves as a point to grab the build site with, and relocate it. We also implemented Mecanum wheels as they have lots of traction and less friction, which makes less difficulty for smoother movement. Finally, we used a claw and grabbing system in the front of the robot in order to move the foundation for extra points during autonomous.